Just like every other field, AI is making waves, and why not? It’s a leap forward in how we build things. Construction has always been about efficiency—getting more done with less waste, fewer delays, and better quality. AI fits right into that.

We’ll look at a few types of AI in construction and how they’re showing up on job sites. It might seem like science fiction, but it’s really just another tool in our toolbox.

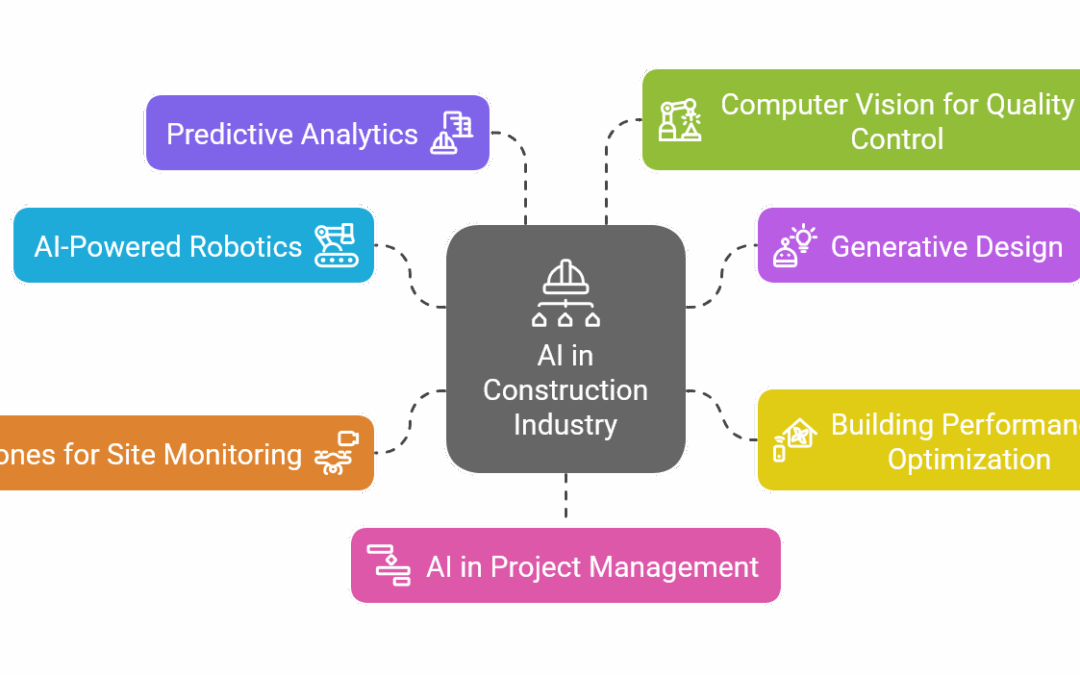

Core AI Technologies in the Construction Industry

In 2023, AI in the construction market was already worth about $2.93 billion. By 2030, it’s expected to skyrocket to nearly $17 billion, a yearly growth rate of 26.9%.

AI-Powered Robotics

Robots aren’t new, but when you add AI, they’re a whole new animal. AI-powered robots can “learn” and handle complex tasks on job sites without breaking a sweat.

For example, AI-powered bricklaying robots, like Hadrian X from Fastbrick Robotics, can lay up to 1,000 bricks an hour—with crazy-good accuracy.

Here are some more robotics applications in the construction industry:

- Concrete pouring and finishing

- Welding and steel beam placement

- Painting and surface finishing

- Site inspections and monitoring

- Demolition and site cleanup tasks

Generative Design

Generative design can generate hundreds or thousands of 3D models based on set rules, like material costs, structural strength, and sustainability.

AI can analyze structural integrity, energy efficiency, and long-term maintenance needs before laying a single brick. It helps cut waste, reduce costs, and optimize projects from day one. Instead of relying solely on human intuition, firms get data-backed designs that balance aesthetics, durability, and functionality.

This technology is especially useful for complex projects, such as skyscrapers or bridges, where small design changes can have a massive impact.

Building Performance Optimization

AI is even making buildings work better after they’re built. Most traditional building systems run on preset schedules. The air conditioning kicks in at a set time, the lights turn off at night, and that’s about it. But AI goes way beyond that. It predicts when and where energy will be needed and adjusts things automatically.

AI-powered systems, especially ones using Model Predictive Control (MPC), can boost energy efficiency by 10% to 40%. It means less wasted power and a building that runs smoother without anyone lifting a finger.

If more buildings start using AI, the U.S. could cut energy use and CO₂ emissions in medium office buildings by about 8%.

Drones for Site Monitoring

In 2020, over 50% of construction companies in the U.S. were already using them for project monitoring. That number has likely climbed since, and for good reason.

Drones offer a 61% improvement in data quality, meaning better insights, fewer mistakes, and faster project completion.

Project managers had to rely on manual inspections, outdated blueprints, and inconsistent progress reports. If something went wrong, they often found out too late. Now, drones can capture real-time aerial views, create 3D site models, and even track progress against digital plans—all in minutes.

Here are a few key reasons why drone tech is getting popular in the construction industry:

- Speed and efficiency: A drone can scan an entire site in minutes, whereas humans would take hours (or days).

- Better safety: No more sending workers into hazardous zones to check progress.

- Cost savings: Fewer errors mean fewer expensive fixes later on.

- More data, better decisions: High-quality drone footage gives project managers a full site overview.

Predictive Analytics

AI analyzes data from past projects, real-time market trends, and on-site conditions to predict costs, risks, and safety concerns before they become major issues. Project forecasting with AI also helps companies avoid budget overruns and optimize resource planning.

AI can track material price fluctuations, labor costs, and supply chain delays to estimate costs, helping firms avoid financial surprises. In risk management, predictive analytics identifies potential delays, equipment failures, and unreliable subcontractors so project managers can adjust plans before problems arise.

Jean-Simon Venne, co-founder and CTO of BrainBox AI, compares their AI’s predictive capabilities to time travel, stating: “We go to the future, see how terrible it will be in two hours, and change that.”

Computer Vision for Quality Control

With the computer vision market hitting $25.8 billion by 2024, industries worldwide are embracing this technology.

Traditionally, quality control relied on manual inspections, where supervisors walked the site, checked measurements, and ensured that everything was up to code. But this approach has major flaws:

- It’s slow: Inspections take time, delaying progress.

- It’s inconsistent: Different inspectors might spot different issues.

- It’s reactive, not proactive: By the time an issue is noticed, it might already be expensive to fix.

Instead of replacing human inspectors, computer vision acts as a second set of eyes. It uses AI to automatically scan work areas, compare progress to digital plans, and flag any inconsistencies in real-time.

AI in Construction Project Management

Traditionally, construction project management required a team of experienced project managers, endless spreadsheets, and a lot of stress. But by 2030, AI is expected to automate 80% of project management tasks.

Cloud-based ERP systems powered by AI help streamline everything from budgeting to scheduling, ensuring project managers have real-time access to data from any location.

AI can take over the repetitive tasks that slow project managers down. Here’s where AI is already making an impact:

- Manage resource allocation such as worker availability, and material deliveries to create optimized schedules.

- Adjust plans for weather delays, supply chain disruptions, or labor shortages.

- Predict cost overruns based on past projects, material price trends, and potential risks.

- Track permits, contracts, and compliance requirements with automatic alerts.

- Identify potential risks like subcontractor delays, equipment failures, or safety hazards.

- Automate daily progress updates and generate reports for stakeholders.

- Use AI-powered chatbots to answer common worker and supplier questions.

- Monitor job site productivity and suggest workflow improvements.

- Real-time dashboards to give project managers instant insights into costs and schedules

AI Adoption Trends in the Construction Industry

The construction industry is on the edge of a major AI shift. However, adoption has been uneven and slow, especially among smaller firms. As of early 2025, only just over 2% of U.S. construction companies reported using AI in recent weeks. In the Netherlands, only 4.7% of construction companies had adopted AI technologies as of 2023.

Larger construction teams are adopting AI at much higher rates. 7.2% of companies with 250+ employees have already implemented AI, compared to just 5.5% of firms with fewer than five employees.

While estimates suggest that the AI market in the construction industry will hit $14.72 billion by 2030, with an annual growth rate of 24.31%, many companies are still hesitant to integrate AI into their daily operations.

Even with AI’s promise of efficiency and cost savings, many in the industry fear its impact on jobs. In the U.S., 71% of employees express concerns about AI, with 75% fearing job obsolescence and 65% uneasy about AI replacing their roles.

AI can automate tasks like cost estimation, scheduling, quality control, and site monitoring, reducing the need for manual oversight. However, it’s not a direct replacement for construction labor, craftsmanship, or decision-making.

Benefits of AI Adoption in Construction

Let’s break down the biggest benefits of AI in construction:

Increased Productivity

Productivity has always been a challenge in construction, and project delays are very common. AI is starting to change that. A McKinsey study found that AI could boost construction productivity by up to 20%.

Zaha Hadid Architects, a firm known for its futuristic, complex designs, reported that AI integration doubled or tripled productivity in early-stage competition design. In mid-stage design preparation, AI increased productivity by 50%.

Why? Because AI-powered design tools can help construction managers:

- Generate and evaluate multiple design options instantly.

- Detect structural inefficiencies early.

- Automate repetitive design tasks.

Cost Reduction

AI helps firms cut costs without cutting quality. Whether optimizing materials, improving workforce efficiency, or reducing rework, AI makes construction more cost-effective.

Norwegian construction firm AF Gruppen used AI to test different material and workforce combinations during the construction of a $560 million high-rise in Oslo. The result? A 15% reduction in project costs.

In another example, Juneau Construction combined drones and AI to gather and analyze data before pouring concrete on a 31-floor high-rise project. This small adjustment saved $40,000 and cut manual processing time by 10 hours per report.

Sustainability and Waste Reduction

Historically, contractors pad their material orders to avoid shortages, often leading to excess materials being discarded.

AI eliminates the guesswork by analyzing project designs, historical data, and supplier inventories to calculate the exact amount of materials required. AI-driven material optimization can reduce over-ordering and waste by up to 15%.

Even with better planning, some waste is unavoidable. But AI is helping recover more recyclable materials. AI-driven waste management systems can increase the recovery of recyclable materials by up to 25%, using:

- Smart sorting systems that scan construction debris and separate recyclable materials.

- Drones and sensors that analyze site waste in real-time.

- AI-powered tracking to monitor waste output.

Competitive Advantage in the Industry

Not every company is jumping on the AI bandwagon right away. Some still think it’s just a buzzword or too complicated. What’s going to happen to companies that skip AI in five or ten years? Will they still be competitive, or will they fall behind?

According to Accenture, artificial intelligence could boost the construction industry’s profits by 71% by 2035.

If you’re in construction right now, you have to ask yourself—do you want to wait until everyone else figures out AI, or do you want to get ahead of the game?

Site Safety

Construction is one of the most dangerous industries in the world. Heavy machinery, high-risk tasks, and unpredictable site conditions make accidents a constant threat.

Companies that adopt AI-powered wearables and predictive analytics will see fewer accidents, lower insurance costs, fewer potential hazards, and better worker protection.

Imagine a worker wearing a smart vest or helmet that tracks their movements, posture, and even fatigue levels. AI-powered wearable devices can detect early signs of exhaustion, overheating, or unsafe body positions that might lead to injuries.

If a worker is moving erratically or slowing down due to fatigue, the system can send an alert, allowing supervisors to intervene before a serious accident occurs. These devices can also track exposure to hazardous conditions like extreme heat, cold, or toxic fumes.

Real-World Applications of AI in Construction Projects

Here are some case studies showing AI-powered tools in action:

Terabase’s AI Robotics for Faster Solar Farm Construction

Traditionally, solar farms require large teams working long hours to assemble, install, and wire thousands of solar panels. But Terabase is changing that with AI-driven robotics and automation.

Terabase has developed an AI-powered mobile assembly line that:

- Prefabricates sections of the solar farm on-site, cutting manual labor.

- Uses automated off-road vehicles to deliver and install solar panels.

- Employs robotic systems to wire panels and complete installations without human lifting.

This resulted in the entire construction process being twice as fast as traditional methods while improving build quality and reducing worker fatigue.

Smarter HVAC Systems for Energy Savings by BrainBox AI

45 Broadway, a 32-story office building in downtown Manhattan, was struggling with high energy costs. The building’s HVAC system ran on outdated thermostats, leading to inconsistent temperatures and wasted energy.

To comply with New York City’s Local Law 97, which limits greenhouse gas emissions from buildings, the owners installed BrainBox AI. This AI system:

- Uses live sensor data (temperature, humidity, wind speed, sun exposure, and occupancy patterns).

- Predicts future temperature shifts and adjusts HVAC settings proactively.

- Optimizes thousands of HVAC components every five minutes for peak efficiency.

After 11 months of AI-powered HVAC management:

- 15.8% reduction in HVAC-related energy consumption.

- $42,000 saved in energy costs.

- 37 metric tons of CO₂ emissions were prevented.

Challenges and Solutions of Adopting AI in Construction

Let’s break down the biggest roadblocks keeping construction firms from going all-in on AI:

Data Privacy and Security Risks

AI systems run on data, but where does that data go? Construction projects involve sensitive blueprints, financial details, and client information. Firms worry about cybersecurity threats and whether their AI providers can protect critical data from hacks or leaks.

To mitigate these risks, companies must choose AI providers with strong security measures, such as data encryption, secure cloud storage, and strict access controls. Construction professionals should also implement internal cybersecurity policies.

Integration with Existing Workflows

Most construction firms already have established workflows, project management tools, and operational methods.

Artificial intelligence needs to be phased in gradually, with training programs and hybrid workflows that mix human workers with AI automation.

Construction firms have unique workflows, and off-the-shelf AI tools might not fit every project. Custom AI solutions for projects allow companies to tailor AI capabilities to their specific needs.

Lack of AI Expertise in the Construction Sector

Most construction firms don’t have AI experts on staff. Even large companies struggle to find professionals who understand both AI and construction workflows. Without the right talent, even the best AI tools won’t be used to their full potential.

Conclusion

The question isn’t if companies should adopt it—but how fast they can start using it before their competitors do. The companies that jump on it now are going to crush the competition, and the ones that drag their feet will be stuck trying to play catch-up.

If your competitors start using AI first, they’ll finish projects faster and cheaper than you, win more bids, and make more money.

So the big question is this: Are you ready to jump in now, or will you wait until you’re forced to? Because by then, it might be too late.

FAQs

Can small construction companies afford AI?

Yes. Many AI tools are now available as subscription-based services (AI-as-a-Service), meaning you don’t need a huge upfront investment. Small firms can start with budgeting AI and scheduling software before moving to more advanced AI applications.

Is AI reliable enough to make construction decisions?

AI is great at analyzing data and spotting problems, but humans still need to make the final call. The best approach is to use AI as a support tool rather than trusting it completely.

Can AI help with material shortages and supply chain issues?

Yes. AI can track supplier trends, predict delays, and suggest backup options before shortages happen. This helps firms stay ahead of supply chain problems instead of reacting when it’s too late.